Tempered glass has become a staple in modern construction, interior design, and safety applications. But when it comes to custom tempered glass, many people are unaware of its unique advantages, production process, and common use cases. This guide aims to demystify the topic for anyone considering custom glass solutions, whether for a home project, office space, or commercial installation.

What Is Custom Tempered Glass?

Tempered glass is a type of safety glass that has been heat-treated to increase its strength compared to regular annealed glass. When it is customized, it means the glass is fabricated to specific dimensions, shapes, and edge finishes to suit the exact requirements of a project, notes the Sun-Pro Realty and Management team.

This glass is particularly known for:

- Its ability to resist thermal stress

- Breaking into blunt granules instead of sharp shards

- Adhering to building safety codes across the U.S.

Why Is Tempered Glass Customized?

Standard-sized sheets of tempered glass are often inadequate for unique architectural elements or specific product designs. Customization allows for:

- Tailored sizing and cutouts (e.g., for handles, hinges, or vents)

- Specific edge finishing (beveled, polished, or seamed)

- Unique shapes and thicknesses

- Compliance with glass thickness standards

The Tempering Process: How Is Tempered Glass Made?

Understanding the tempering process helps you appreciate the safety and durability of custom glass. Here’s how it works:

- Cut to Size First: Glass must be cut to its final shape before tempering,post-tempering cutting is impossible due to the internal stresses.

- Edge Finishing: Edges are smoothed to prevent premature breakage during heating.

- Heating: The glass is heated to over 1100°F (593°C).

- Rapid Cooling: The surface is rapidly cooled using high-pressure air jets. This causes the outer surfaces to compress and the interior to remain in tension, creating internal stress that strengthens the glass.

Key Benefits of Custom Tempered Glass

- Improved Safety

Tempered glass is engineered to shatter into small, blunt pieces, significantly reducing injury risk in case of breakage. This is critical in areas with children, high traffic, or where impact resistance is necessary.

- Thermal Resistance

The glass withstands high temperatures and sudden changes in heat, making it ideal for oven doors, skylights, and glass cooktops.

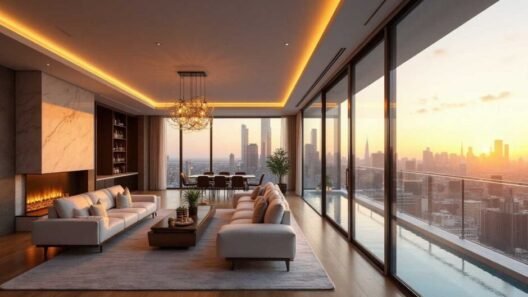

- Design Versatility

Custom tempered glass allows for unique design applications in modern architecture. You can request frosted, tinted, or patterned finishes, opening a wide range of aesthetic possibilities.

- Durability & Strength

Tempered glass is up to five times stronger than standard glass, which makes it perfect for structural applications like balustrades, tabletops, and facades.

Common Uses of Custom Tempered Glass in the U.S.

Residential Applications

- Shower Enclosures: Frameless shower doors require precise measurements and often include hardware cutouts.

- Glass Railings: For decks, staircases, and balconies,especially in coastal homes.

- Glass Table Tops: Protect wood surfaces or create a sleek modern look.

Commercial Applications

- Storefronts & Display Cases: Retail environments rely on both safety and visual clarity.

- Office Partitions: Used to maintain an open-concept layout without sacrificing privacy (often combined with frosting).

- Interior Glass Doors: Offices opt for glass doors with customized logos etched or printed.

Automotive & Industrial Applications

- Vehicle Windows: Back and side windows of cars are usually made from tempered glass.

- Machinery Protection Shields: Industrial equipment often uses custom-sized tempered glass for operator safety.

Types of Tempered Glass Finishes

Depending on the desired function or aesthetic, custom tempered glass can be finished in various ways:

- Clear Tempered Glass

Offers maximum transparency; ideal for windows and partitions.

- Tinted Tempered Glass

Available in shades like bronze, gray, and blue to reduce glare and UV exposure.

- Frosted or Acid-Etched Glass

Perfect for privacy applications such as bathroom windows and office meeting rooms.

- Patterned and Textured Glass

Used where both design and privacy are desired, such as in decorative panels.

Understanding Glass Thickness Standards

In the U.S., glass thickness for tempered panels ranges from 1/8 inch (3mm) to ¾ inch (19mm) depending on application:

- 1/8” (3mm): Best for lightweight applications like picture frames

- 3/16” to 1/4” (5–6mm): Common for window panes and tabletops

- 3/8” to ½” (10–12mm): Ideal for frameless shower doors or railings

- 5/8” to ¾” (15–19mm): Heavy-duty applications like structural panels

Always confirm with your local building codes and safety regulations before choosing glass thickness.

How Custom Tempered Glass Is Measured and Ordered

To order custom tempered glass, measurements must be extremely precise. In fact, tolerances are typically within ±1/16 of an inch. Here’s a basic guide:

- Measure Width & Height: Always in inches, and always twice to confirm accuracy.

- Note the Thickness: Based on use-case and safety code.

- Specify Edge Finish: Seamed (standard), polished (premium), or beveled (decorative).

- Add Cutouts (if needed): For hinges, locks, or mounting hardware.

- Choose Your Finish: Clear, tinted, frosted, etc.

Pro Tip: Always deduct about 1/8 inch from frame measurements to allow for easy installation and thermal expansion.

Is Tempered Glass the Same as Laminated Glass?

- While both are safety glass types, they differ significantly:

- Tempered Glass: Strengthened by heat, breaks into chunks.

- Laminated Glass: Consists of two or more layers with a plastic interlayer (PVB or EVA), and stays in place when shattered.

Tempered glass is preferred where impact resistance is key, while laminated glass is better for soundproofing and UV protection.

Limitations of Custom Tempered Glass

Even though it’s highly durable and safe, tempered glass isn’t indestructible:

- Not Cuttable After Tempering: Any changes must be made before tempering.

- Sensitive to Edge Damage: Damage to the edges can trigger spontaneous breakage.

- Slight Optical Distortion: Due to the heating process, especially noticeable on larger sheets or when viewed at an angle.

Building Code Compliance & Safety Certifications

In the U.S., custom tempered glass must comply with standards set by:

- ANSI Z97.1:Safety glazing materials for buildings

- CPSC 16 CFR 1201:Federal regulations for architectural glazing

- ASTM C1048:Standard specification for heat-treated flat glass

Make sure to check whether the glass you’re sourcing comes with the appropriate safety stamp or etching.

Final Thoughts

Custom tempered glass plays a pivotal role in modern design and safety across residential, commercial, and industrial applications. It offers unparalleled strength, aesthetic flexibility, and protection,making it a superior choice for nearly every context where glass is used.

By understanding its benefits, limitations, and technical specifications like glass thickness standards and edge finishing, you can make well-informed decisions for your next project. Whether you’re building a home, upgrading a storefront, or installing a new shower enclosure, custom tempered glass is a solution that combines beauty, functionality, and safety.